THE FACETING PROCESS

THE FACETING PROCESS

Once the rough is sawed and ready for cutting, the faceter roughly creates the shape by which the gemstone will be cut - this is termed ‘pre-forming’ and is it is done by hand using a heavily embedded diamond lap and trust me - it bites your index finger and thumb. Then it is time for the stone to be ‘dopped’. ‘Dopping’ is a process whereby the rough stone is attached to a brass peg with melted jewellers wax which is as hard as rock once cooled. Dops come in three styles - flat, cone and V-shaped (HOG has designed and produced a fourth - a square dop for square shaped stones).

The dopping process is equally as important as the rough pre-forming process as the stone needs to be centered on the dop perfectly, in order to make sure that no more weight is lost on the stone before the actual cutting process is started. Once cooled, the dop is inserted into the head of the Facetron Mast. House of Gaea manufactures and sells its own brass dops designed for use in the Facetron head.

The dopping process is equally as important as the rough pre-forming process as the stone needs to be centered on the dop perfectly, in order to make sure that no more weight is lost on the stone before the actual cutting process is started. Once cooled, the dop is inserted into the head of the Facetron Mast. House of Gaea manufactures and sells its own brass dops designed for use in the Facetron head.

Once cooled, the dop is inserted into the head of the Facetron Mast (seen in the title picture), set at an angle of 90 degrees and the girdle is cut and polished. Once the girdle is done, it is time for the pavilion (bottom) or crown (top) to be cut, which is first depends on the expertise of the Faceter or the preference of the Faceter. On a newly cut stone HG prefers to cut the pavilion first and table 2nd. In the case of repairing or re-cutting a stone HG prefers to cut the table first as this allows space to work toward maintaining weight and re setting the pavilion angles...shallow for lack of pavilion space. Once the pavilion mains are cut (in the case of a brilliant cut) and polished, the girdle facets are cut and polished.

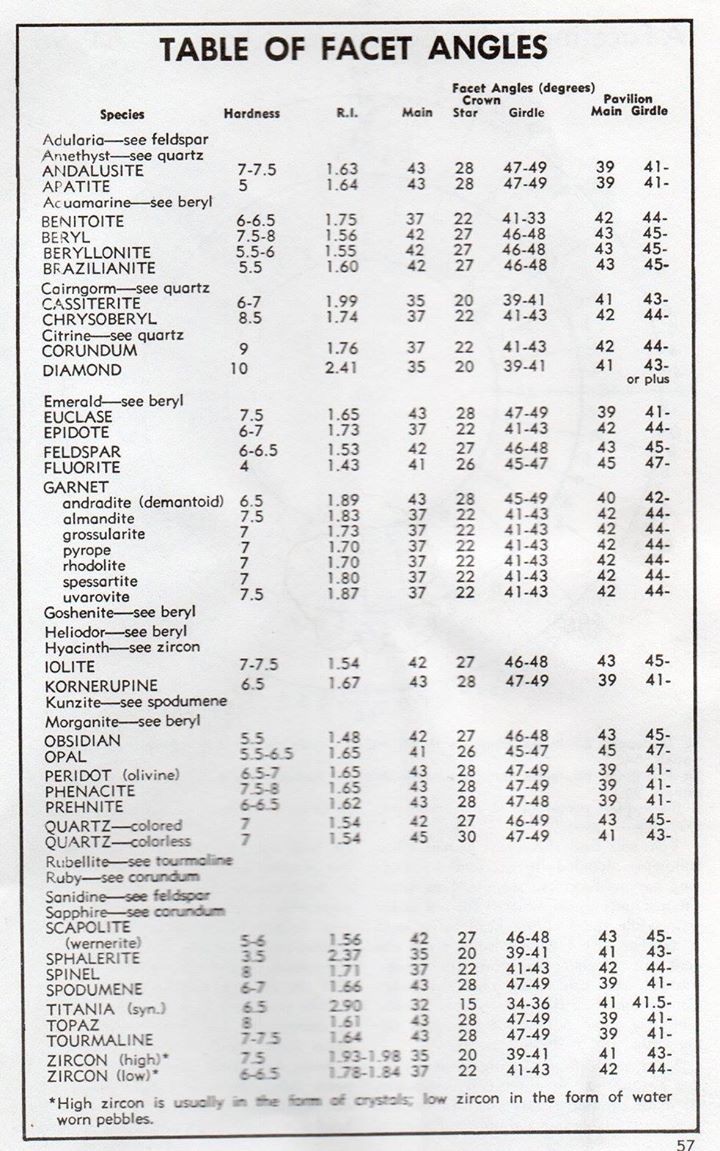

Each different gemstone has a scientifically perfect angle for each facet in order to maintain the best possible cut of a stone. Quartz for example is cut at 43 degrees for the pavilion main facets and 42 for the crown mains, but Ruby is set at 42 degrees for the pavilion and 37 for the crown. The scientific angles are only a guide, it’s up to the stone in the end.

Each different gemstone has a scientifically perfect angle for each facet in order to maintain the best possible cut of a stone. Quartz for example is cut at 43 degrees for the pavilion main facets and 42 for the crown mains, but Ruby is set at 42 degrees for the pavilion and 37 for the crown. The scientific angles are only a guide, it’s up to the stone in the end.

Once the pavilion is cut the stone needs to be transferred to a table dop using a transfer jig so that the crown can be cut or vise versa. This involves heating the wax on the cut stone so that it is soft enough to transfer into heated wax in the receiving stone...a juggling act with heat.

Once attached the two dops are left to cool and harden still attached. Once hardened a gentle heat is applied to the main dop in order to release the stone attached to the transferred dop. The table is then cut using a 45 degree table dop. Traditionally the table should make up 30 % of the surface of the table but it is also up to the stone and Faceter. In the case of a Brilliant cut, the crown main facets are then cut, along with the girdle facets and then star facets and then polished. Some stones, like Diamond are given an extra facet, known as a ‘culet’ - a tiny facet on the tip of the pavilion but that lies with the faceters’ personal choice on gemstones.